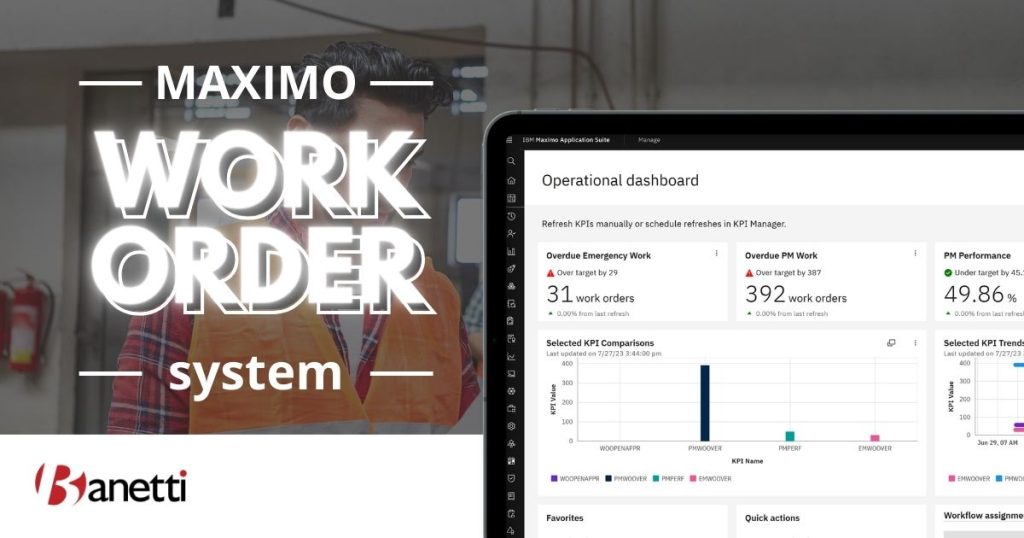

What is Maximo Used For | Features, Functionality, and Purpose

With the ever-growing complexity of assets, coupled with the need for compliance with regulations and standards, traditional manual methods for managing assets are no longer sufficient. Businesses require modern-day tools equipped with advanced features and functionalities to tackle the challenges of asset management effectively. This is where IBM Maximo steps in.

What is Maximo Used For | Features, Functionality, and Purpose Read More »